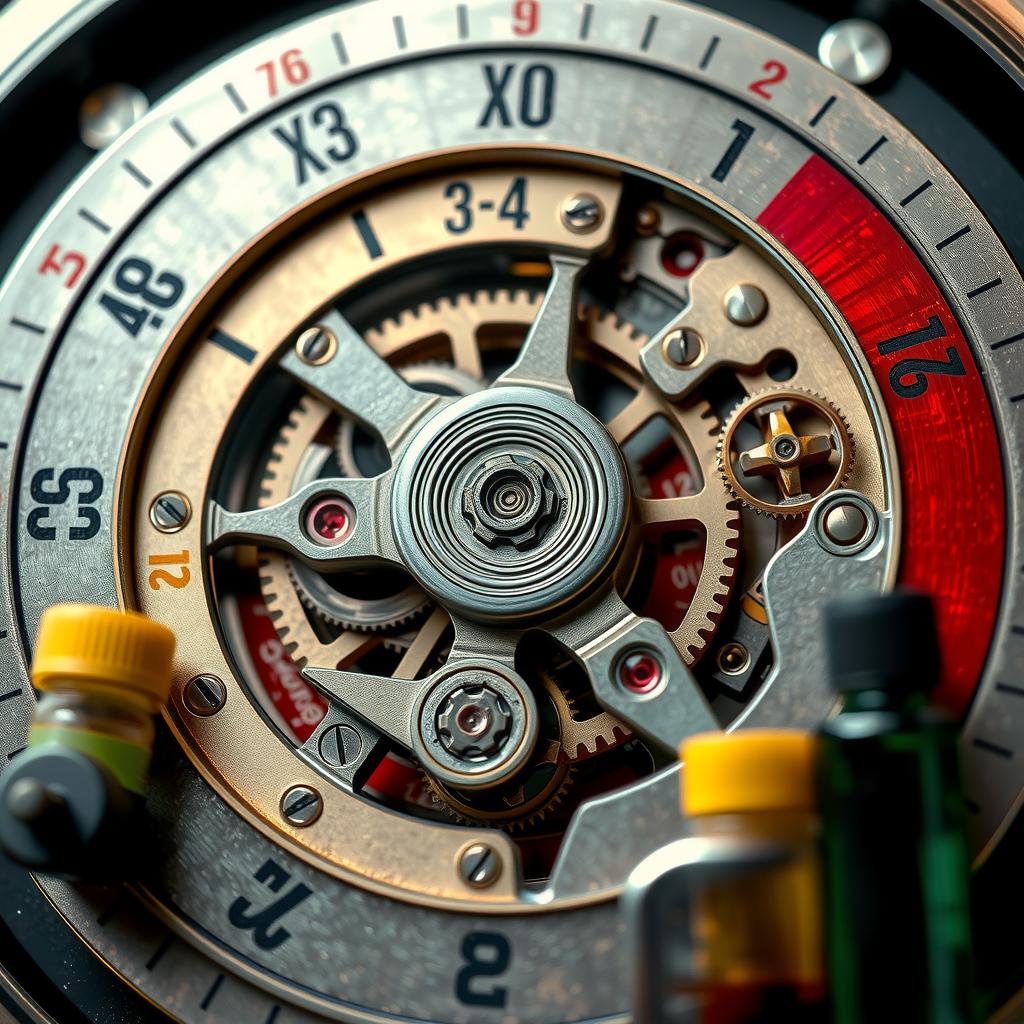

In the world of precision instruments, the smooth operation of mechanical dials is essential for both functionality and user experience. Whether it’s a vintage clock or a modern gauge, users often encounter the frustrating phenomenon of stiff or unresponsive dials that can disrupt their daily tasks. This issue not only diminishes the performance of these devices but also raises concerns about long-term wear and tear. The importance of proper dial maintenance cannot be overstated—without regular care, even the most meticulously crafted mechanisms can falter over time. Fortunately, there is an effective solution to ensure that mechanical dials continue to perform at their best: finding the best lubricant for mechanical dials.

Lubrication plays a crucial role in maintaining these intricate systems by reducing friction and preventing rust buildup. However, with numerous lubrication solutions available on the market, selecting the right product can be daunting for many users. It’s vital to choose a lubricant specifically designed for delicate mechanisms like clocks or gauges to avoid damaging sensitive parts or impairing functionality further. The best lubricant for mechanical dials provides an ideal balance between protection and performance while ensuring that every turn is as effortless as possible.

As readers delve deeper into this article, they will uncover valuable insights on how various lubricants compare when it comes to effectiveness in preserving longevity and enhancing usability in mechanical applications. By exploring factors such as viscosity, application methods, and compatibility with different materials commonly found in precision instruments, individuals will be empowered to make informed decisions regarding dial maintenance strategies tailored to their needs.

Understanding which products qualify as the best lubricant for mechanical dials requires examining real-world scenarios alongside expert recommendations from clock repair professionals who consistently work with these intricate devices. Ultimately, this guide aims not only to illuminate optimal choices but also instill confidence in users seeking reliable ways to restore—and sustain—their treasured equipment’s operational integrity through effective lubrication practices.

Join us on this informative journey into discovering how choosing wisely among lubrication solutions can lead directly toward achieving lasting results in maintaining those cherished mechanical dials!

Key Points:

- The Importance of Proper Lubrication: The smooth operation of mechanical dials hinges on effective lubrication. Utilizing the best lubricant for mechanical dials can prevent issues such as sticking or stuttering, ensuring that precision instruments function as intended. Regularly applying a suitable lubricant is essential to maintain optimal performance and prolong the lifespan of these delicate devices.

- Reducing Friction for Enhanced Performance: Friction within mechanical dials can lead to significant wear and tear over time. By choosing an appropriate product, users can significantly minimize this friction, which ultimately enhances efficiency in clock repair and maintenance tasks. The right selection will not only contribute to smoother movement but also improve the accuracy and responsiveness crucial for any precision instrument.

- Navigating Lubrication Options Effectively: With numerous lubrication solutions available, understanding their properties becomes vital when seeking the best lubricant for mechanical dials. Users should prioritize formulations that are specifically designed for dial maintenance, focusing on durability and effectiveness in reducing friction. This knowledge empowers individuals to make informed decisions about maintaining their cherished instruments seamlessly over time.

Understanding Lubrication in Mechanical Dials

The Importance of Proper Lubrication for Precision Instruments

In the realm of precision instruments, such as mechanical dials, proper lubrication plays a pivotal role in ensuring smooth operation and longevity. Lubricants serve not merely as a means to reduce friction but also act as protective agents that shield intricate components from wear and corrosion. A well-lubricated mechanical dial can significantly enhance performance, allowing for accurate readings and efficient functionality over time. When selecting the best lubricant for mechanical dials, it is essential to consider formulations designed specifically for the materials used in these delicate devices. These specialized lubricants provide optimal viscosity levels that facilitate seamless movement between gears and other moving parts.

The mechanics behind dial maintenance are intricately tied to effective lubrication solutions. For instance, when maintaining vintage clocks or sophisticated measuring instruments, technicians often recommend using high-quality lubricants that can withstand varying temperatures while providing adequate protection against contaminants such as dust or moisture. In this context, choosing the best lubricant becomes paramount; it not only ensures reliable operation but also minimizes the need for frequent clock repair interventions due to premature wear caused by inadequate lubrication.

Furthermore, a lack of proper lubrication can lead to increased friction within mechanical dials which may result in sluggish movements or inaccurate readings—a scenario no operator wants to encounter. Regular application of an appropriate lubricant fosters an environment where all components work harmoniously together without unnecessary strain on any single part. This consideration is crucial especially given how finely tuned precision instruments are; even minor deviations can disrupt their intended functions dramatically.

Ultimately, understanding how different lubricants interact with various materials helps users make informed choices regarding their maintenance practices. Whether one is dealing with vintage machinery or modern equipment equipped with advanced technology—such knowledge ultimately leads towards making better decisions about sustaining these valuable tools’ operational integrity over extended periods of use.

Thus, employing suitable lubrication solutions contributes directly to both enhanced performance metrics and prolonged service life for mechanical dials across diverse applications—from industrial settings requiring precise measurements down to treasured family heirlooms needing careful preservation through thoughtful upkeep strategies involving high-grade products like the best lubricant for mechanical dials available on today’s market.

Choosing the Right Lubricant for Optimal Functionality

Understanding Key Properties of Lubricants

Selecting the right lubricant is crucial for ensuring optimal functionality, especially when dealing with precision instruments such as mechanical dials. Various factors come into play in this process, including viscosity, temperature stability, and compatibility with materials. Viscosity refers to a lubricant’s thickness or resistance to flow; it is essential that the best lubricant for mechanical dials has an appropriate viscosity level to provide effective lubrication without causing drag or friction. Temperature stability also plays a significant role since lubricants can break down under extreme conditions, potentially compromising their effectiveness in dial maintenance. Furthermore, compatibility with different materials used in mechanical dials must be considered to prevent any adverse chemical reactions that could lead to deterioration of components.

The Importance of Additives

Additives are another critical aspect when selecting lubricants for mechanical applications. They enhance performance characteristics and protect against wear and tear in high-precision devices like clocks and watches. For instance, anti-wear additives significantly improve longevity by forming protective films on surfaces during operation while reducing metal-to-metal contact which can result in damage over time. Additionally, choosing a formulation with rust inhibitors ensures that moisture does not compromise the integrity of internal parts—a vital consideration for clock repair specialists who aim for lasting results. Therefore, opting for the best lubricant specifically designed for mechanical dials can make all the difference between smooth operation and premature failure.

Evaluating Application Methods

When evaluating lubrication solutions suitable for maintaining mechanical dials, one must consider application methods as well—whether through manual application or using specialized tools designed to deliver precise amounts directly onto gears and moving parts. A controlled method helps avoid excess buildup of grease or oil that might attract dust particles leading to further complications down the line during routine maintenance checks on precision instruments like clocks or other delicate mechanisms requiring meticulous care throughout their lifespan. Thus understanding these nuances will guide users toward making informed decisions about which product serves them best.

Balancing Performance with Longevity

Ultimately, there’s an intricate balance between performance efficiency and longevity when selecting lubricants tailored specifically towards complex systems involving mechanical dials within various devices—from antique clocks needing careful preservation efforts aimed at enhancing overall functionality—to modern precision equipment demanding reliability under rigorous conditions encountered daily in industrial settings alike! This comprehensive approach emphasizes how paramount it is not just finding any good quality option but honing into what truly stands out—the best lubricant suited perfectly targeting those unique challenges faced regularly by technicians involved primarily focused around dial maintenance practices ensuring smooth operations persistently maintained across generations ahead!

Exploring Top Lubricants for Dial Maintenance

Discovering Effective Solutions for Precision Instruments

In the realm of dial maintenance, enthusiasts and professionals alike recognize that choosing the right lubricant is pivotal for ensuring smooth operation. Among the various products available, one stands out as the best lubricant for mechanical dials: synthetic oils specifically formulated to cater to intricate mechanisms found in clocks and other precision instruments. These lubricants not only reduce friction but also provide excellent protection against wear and moisture. Their ability to maintain a consistent viscosity over a wide temperature range makes them ideal for both vintage clock repairs and modern applications. The unique properties of these synthetic lubes allow them to penetrate tiny spaces within mechanical dials, creating a barrier that prevents dirt accumulation while enhancing movement efficiency.

Essential Characteristics of High-Quality Lubrication Solutions

Ensuring Longevity and Performance

When evaluating lubrication solutions for dial maintenance, it is crucial to consider several characteristics that define their effectiveness. The best lubricants are often characterized by their low volatility and stability under varying environmental conditions. For instance, high-quality lubricants will resist breaking down at elevated temperatures or when exposed to humidity—factors detrimental to clock performance over time. Furthermore, an effective lubricant must possess superior adhesive qualities; this ensures it clings effectively without migrating away from essential components during operation cycles. By utilizing such advanced formulations tailored specifically as a best lubricant for mechanical dials, users can experience longer-lasting performance with minimal maintenance requirements—a vital aspect in preserving valuable timepieces.

Balancing Application Techniques with Lubricant Selection

Mastering Clock Repair Through Proper Methods

The application technique plays an equally significant role in achieving optimal results during dial maintenance. Even the best lubricant can fail if applied incorrectly; therefore, professionals advocate using precision tools designed specifically for delicate tasks like clock repair or maintaining mechanical dials on various instruments. A fine applicator allows precise delivery of lubrication exactly where needed without excess overflow onto surrounding areas—an essential consideration given how minute some mechanisms are constructed today! Additionally, enthusiasts should be mindful about applying just enough product; going overboard may lead not only unnecessary waste but could potentially attract more dust particles contrary to intended effects aimed at smooth operation post-maintenance intervention.

Understanding User Preferences: Insights from Professionals

Evaluating Choices Based on Experience

User preferences often shape recommendations when it comes down selecting appropriate lubrication solutions geared towards dial maintenance needs across different contexts—from hobbyists restoring heirloom pieces back into working order all way professional technicians servicing high-end devices routinely . Feedback collected from experienced individuals highlights consistency among those who prefer certain brands touted consistently as delivering reliable outcomes regardless operational demands faced daily ; this includes featuring well-known names synonymous excellence providing robust options within marketplace today . Ultimately , investing quality products such aforementioned ultimately yields dividends longevity functionality enjoyed whenever interacting intricately crafted mechanics driving beauty artistry behind timeless creations embodied through skilled craftsmanship seen throughout history .

Frequently Asked Questions:

Q:What is the importance of using a lubricant for mechanical dials?

A:Using the best lubricant for mechanical dials is crucial as it ensures smooth operation, reduces friction, and minimizes wear and tear on internal components. This maintenance not only enhances performance but also extends the lifespan of precision instruments like watches and gauges.

Q:How often should I apply lubrication to my mechanical dials?

A:The frequency of applying lubrication depends on usage and environmental conditions. It is generally recommended to perform dial maintenance every 6-12 months. Regular application of the best lubricant for mechanical dials can help maintain their functionality, ensuring they operate seamlessly over time.

Q:Are there specific types of lubricants that are better suited for clock repair?

A:Yes, certain formulations are specifically designed for clock repair and restoration. The best lubricant for mechanical dials typically includes synthetic oils or specialized grease that offer excellent viscosity stability and resistance to degradation under varying temperatures, making them ideal choices for maintaining precision instruments effectively.