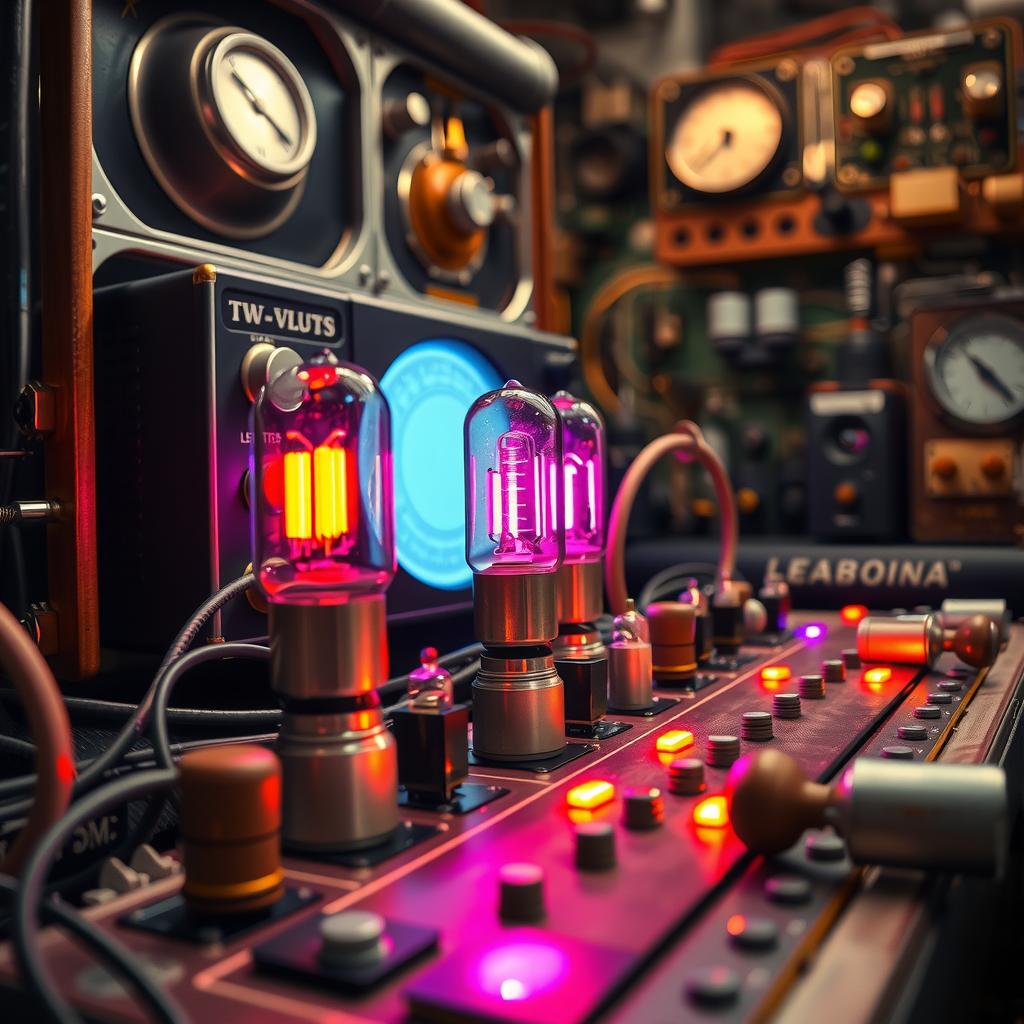

In an age dominated by sleek digital devices, there exists a fervent community of enthusiasts who cherish the warm glow and distinctive audio quality of vintage televisions. But what happens when those cherished relics begin to lose their luster? The answer often lies within the delicate circuitry and, more specifically, the vacuum tubes that power these iconic machines. This raises an intriguing question: How can one ensure that these vital components are functioning optimally? Enter vintage TV vacuum tube testing, a crucial process for anyone involved in electronic repair or restoration.

Understanding the art of tube testing is essential for preserving the integrity of vintage electronics. Unlike modern solid-state technologies, vacuum tubes require specific attention to detail during troubleshooting. Testing methods have evolved over time—ranging from simple multimeter readings to sophisticated dedicated testers designed for precise diagnostics. For hobbyists and professionals alike, mastering these techniques opens up new avenues for enhancing performance and prolonging lifespans.

The core value of this article lies in its ability to demystify vintage TV vacuum tube testing. Readers will gain insights into effective strategies that not only improve their skills but also enhance their understanding of how each component contributes to overall audio quality and visual output. By delving into various methods used in tube testing—from emission tests to transconductance measurements—the discussion aims at equipping enthusiasts with practical knowledge they can apply directly in their projects.

Moreover, as many collectors know all too well, finding replacement parts can be daunting; thus being adept at troubleshooting tubes becomes even more critical. Luckily, this guide promises valuable solutions tailored specifically for navigating challenges related to aging equipment while ensuring seamless operation long into the future.

As readers embark on this exploration of vintage TV vacuum tube testing, they are invited not just to learn but also to engage actively with a community passionate about keeping history alive through technology’s intricate tapestry. So whether one is merely curious or deeply invested in restoring classic sets, understanding how best to test those elusive vacuum tubes stands as an indispensable skill worthy of pursuit—a gateway toward rejuvenating beloved electronics while unlocking hidden potential along the way.”

Key Points:

- Understanding Vacuum Tube Functionality: A deep dive into how vacuum tubes operate and their critical role in vintage TVs. Mastering this aspect is essential for effective vintage TV vacuum tube testing, enabling enthusiasts to identify issues that affect performance.

- Effective Testing Methods: Exploring various techniques for assessing the condition of vacuum tubes. Utilizing proper tube testing methods not only aids in troubleshooting tubes but also enhances overall audio quality, ensuring that classic televisions deliver an optimal viewing experience.

- Empowering Electronic Repair Skills: Gaining knowledge about electronic repair practices related to vintage electronics equips hobbyists with the tools needed for successful restorations. Understanding how to conduct thorough checks through diligent vintage TV vacuum tube testing can help avoid costly repairs while preserving cherished memories associated with these timeless devices.

The Charm of Nostalgia in Electronics

Understanding the Role of Vintage TV Vacuum Tube Testing

In an era where technology evolves at a lightning pace, vintage electronics hold a unique charm that captivates enthusiasts and collectors alike. Among these relics, vintage televisions stand out as prime examples of historical craftsmanship and engineering ingenuity. However, the performance of these classic devices often hinges on the health and functionality of their internal components—most notably, vacuum tubes. As such, vintage TV vacuum tube testing has emerged as a vital practice in preserving not only audio-visual quality but also the integrity of this nostalgic technology. This process involves various testing methods designed to assess the condition and efficacy of vacuum tubes, ensuring that they are capable of delivering optimal performance.

The significance of vintage TV vacuum tube testing cannot be overstated; it serves multiple purposes beyond mere restoration. First and foremost, effective tube testing allows for accurate troubleshooting tubes that may have degraded over time due to usage or age-related wear-and-tear. Technicians skilled in electronic repair can identify which components need replacement or rejuvenation by utilizing specialized equipment designed for this task. With careful examination, they’re able to determine whether a particular tube is still capable of amplifying signals effectively or if its output has diminished significantly—a crucial factor considering how much audio quality can vary based on these small yet pivotal parts.

Moreover, engaging with vintage electronics through tube testing fosters an appreciation for older technologies among new generations who may otherwise overlook them in favor of modern equivalents. By understanding how these systems functioned decades ago—and what makes them unique—enthusiasts contribute to an ongoing dialogue about technological evolution and preservation culture within society today. It’s fascinating how something as simple as proper maintenance can breathe new life into beloved artifacts from yesteryear while simultaneously educating individuals about fundamental principles underlying analog circuitry.

Furthermore, DIY enthusiasts often engage with vacuum tube technology not just from a restoration standpoint but also as partaking in creative projects aimed at crafting personalized sound experiences—be it through music amplification or custom builds replicating iconic designs found throughout history. These endeavors highlight another dimension where knowledge acquired via thorough tube testing, including identifying characteristics like gain levels or distortion factors becomes invaluable when venturing into experimental territory with various setups.

As we dive deeper into understanding vintage television sets—including their intricate inner workings—the role played by meticulous evaluation processes surrounding vacuum tubes emerges clearer than ever before: without adequate attention given toward maintaining those fragile glass cylinders housing electron flow essential for broadcasting signals back then (and even now), one risks losing touch entirely with an important segment representing both our past innovations & legacy advancements made throughout contemporary times’ rapid progression forward towards digital realms filled increasingly more bright screens vying for consumer attention each day!

Understanding the Anatomy of Vacuum Tubes

Exploring the Inner Workings of Vintage Technology

Vacuum tubes, also known as thermionic valves, are fascinating components that played a crucial role in the development of electronic devices, particularly vintage TVs. At their core, vacuum tubes consist of a sealed glass envelope containing a vacuum. Inside this envelope are electrodes: typically an anode (positive electrode), cathode (negative electrode), and sometimes additional grid elements which control electron flow. The fundamental principle behind their operation is thermionic emission—when heated sufficiently, the cathode emits electrons into the vacuum, allowing them to travel toward the anode. These electrons can be manipulated using grids to amplify signals or switch currents on and off. In vintage televisions, vacuum tubes were essential for tasks such as signal amplification and oscillation generation.

When it comes to vintage TV vacuum tube testing, understanding how these components function is vital for effective troubleshooting and repair. Technicians often employ various testing methods to assess whether these tubes are functioning correctly or if they need replacement due to wear over time. Common issues include loss of gain or increased noise levels in audio outputs—both detrimental effects in television reception quality that can arise from failing tubes. Tube testers can measure parameters like emission strength and transconductance; thus providing valuable insights into tube performance during maintenance checks.

The Role of Vacuum Tubes in Vintage TVs

A Pillar of Early Electronic Design

The significance of vacuum tubes extends beyond mere functionality; they represent a pivotal evolution in electronic design within vintage TVs that shaped modern technology’s trajectory. These devices helped establish high fidelity sound through advanced audio processing capabilities unavailable with earlier technologies like crystal sets or mechanical radios. Each component within a vintage TV relied heavily on carefully calibrated vacuum tube circuitry—be it for picture modulation or sound amplification—to deliver quality performance expected by consumers at that time.

Moreover, maintaining proper tube testing practices ensures not only optimal television performance but also longevity for cherished pieces from past decades—a hobbyist’s dream come true amidst today’s fast-paced digital world where technology rapidly evolves! For aficionados engaging with vintage electronics restoration projects, knowing how different types of vacuum tubes affect overall system functionality becomes indispensable knowledge shared among enthusiasts dedicated towards preserving history whilst enjoying nostalgic viewing experiences.

Troubleshooting Techniques for Vacuum Tubes

Ensuring Peak Performance Through Testing Methods

In dealing specifically with troubleshooting tubes, one must recognize signs indicating when intervention is necessary before further damage occurs within a vintage TV set-up utilizing this older infrastructure technology extensively rooted in electrical principles governing electron movement through controlled environments created via evacuated chambers filled solely by electric potential gradients across terminals designated accordingly depending upon circuit requirements established originally during manufacturing processes many years ago!

Common symptoms hinting at underlying problems could manifest through distorted images onscreen coupled alongside audible static sounds emanating from speakers suggesting possible degradation occurring somewhere along signal paths reliant upon functional integrity maintained throughout entire apparatus comprising complex interconnections spanning multiple subassemblies linked together harmoniously producing captivating visual displays combined seamlessly accompanied melodious sounds delighting viewers back then just as much now if properly preserved!

For successful resolution actions needed regarding faulty units involve systematic approaches employing reliable diagnostic equipment assessing voltage readings across respective pins while conducting thorough inspections revealing physical defects such as loose connections corrosion buildup impacting efficiency adversely detracting enjoyment derived from watching classic films series aired long ago making those moments unforgettable forever etched memories held dear nostalgia reigns supreme wherever hearts reside captivated still yearning connection bridging gaps left behind bygone eras enriched significantly thanks largely attributed innovations pioneered through remarkable inventions pioneered first introduced namely—the venerable yet revolutionary vacuum tube!

Effective Vacuum Tube Testing Techniques

Practical Methods for Ensuring Performance in Vintage Electronics

When delving into the world of vintage electronics, particularly with vintage TV vacuum tube testing, one quickly realizes that the art of ensuring optimal performance is as much about knowledge as it is about technique. Various methods exist to test vacuum tubes effectively, and these techniques not only help in troubleshooting common issues but also maintain peak performance over time. A fundamental approach to tube testing starts with visual inspections; technicians often look for signs of physical damage or deterioration, such as burn marks or broken seals. Following this initial assessment, implementing a simple yet effective electronic repair method involves using a dedicated vacuum tube tester, which can accurately measure parameters like emission levels and transconductance. This data provides insight into whether a tube functions properly or needs replacement.

In addition to using testers, understanding the electrical characteristics specific to different types of vintage TV vacuum tubes proves essential. For instance, identifying the correct pin configuration and operating voltages ensures compatibility during testing processes—a step that cannot be overlooked when working on older models where documentation may be scarce. Moreover, maintaining audio quality checks through careful monitoring while conducting tests allows for early identification of potential failures related directly to sound reproduction capabilities—an important factor for enthusiasts who cherish vintage audio fidelity.

Troubleshooting Common Issues with Tubes

Identifying Problems Before They Affect Performance

Troubleshooting tubes requires an analytical eye combined with practical experience in handling various types of vintage electronics. Common issues encountered during vintage TV vacuum tube testing include filament failure or gas leaks within the glass envelope which may result from age-related wear or improper handling over time. To tackle such problems efficiently, technicians are advised first to verify power supply stability since fluctuations can lead directly to suboptimal functioning across multiple components within a circuit involving vacuum tubes.

Furthermore, utilizing methods like substitution—where known good tubes replace suspected faulty ones—can rapidly confirm whether particular units are indeed malfunctioning without extensive diagnostic procedures every time something goes awry. Beyond mere replacement strategies lies preventative maintenance: regular cleaning practices can mitigate dust accumulation affecting connectivity while replacing aged capacitors around areas housing these vital components promotes longevity and reliability throughout diverse applications in both audio systems and television sets alike.

By consistently applying these methodologies alongside critical analysis driven by observations made during hands-on experiences in electronic repair, users will find their success rates markedly improve when engaging with any aspect involving vacuum tube technology—ensuring that enthusiasts continue enjoying high-quality performances long after their devices were released from production lines decades prior.

Frequently Asked Questions:

Q: What are the signs that my vintage TV vacuum tubes may need testing?

A: There are several indicators that suggest your vintage TV vacuum tubes may require testing. Common signs include distorted audio, flickering images, or an overall decrease in performance quality. If your television is not producing sound or visuals consistently, it’s wise to conduct vintage TV vacuum tube testing to identify any faulty components.

Q: How can I perform basic troubleshooting on my vacuum tubes at home?

A: Basic troubleshooting of vacuum tubes can be initiated by visually inspecting each tube for any obvious signs of damage such as cracks or discoloration. Following this visual check, enthusiasts should utilize a dedicated tube tester to assess the functionality of the tubes. This process is essential within the broader realm of vintage electronics, as it allows for effective diagnosis and ensures optimal performance through accurate tube testing methods.

Q: Are there specific tools required for effective vintage TV vacuum tube testing?

A: Yes, having the right tools significantly enhances one’s ability to carry out thorough checks on vintage TVs. Essential equipment includes a reliable tube tester specifically designed for various types of vacuum tubes, along with multimeters for checking voltages and currents during repairs. Additionally, possessing basic electronic repair tools will empower owners to manage their restoration projects confidently while ensuring successful outcomes in their electronic repair practices.