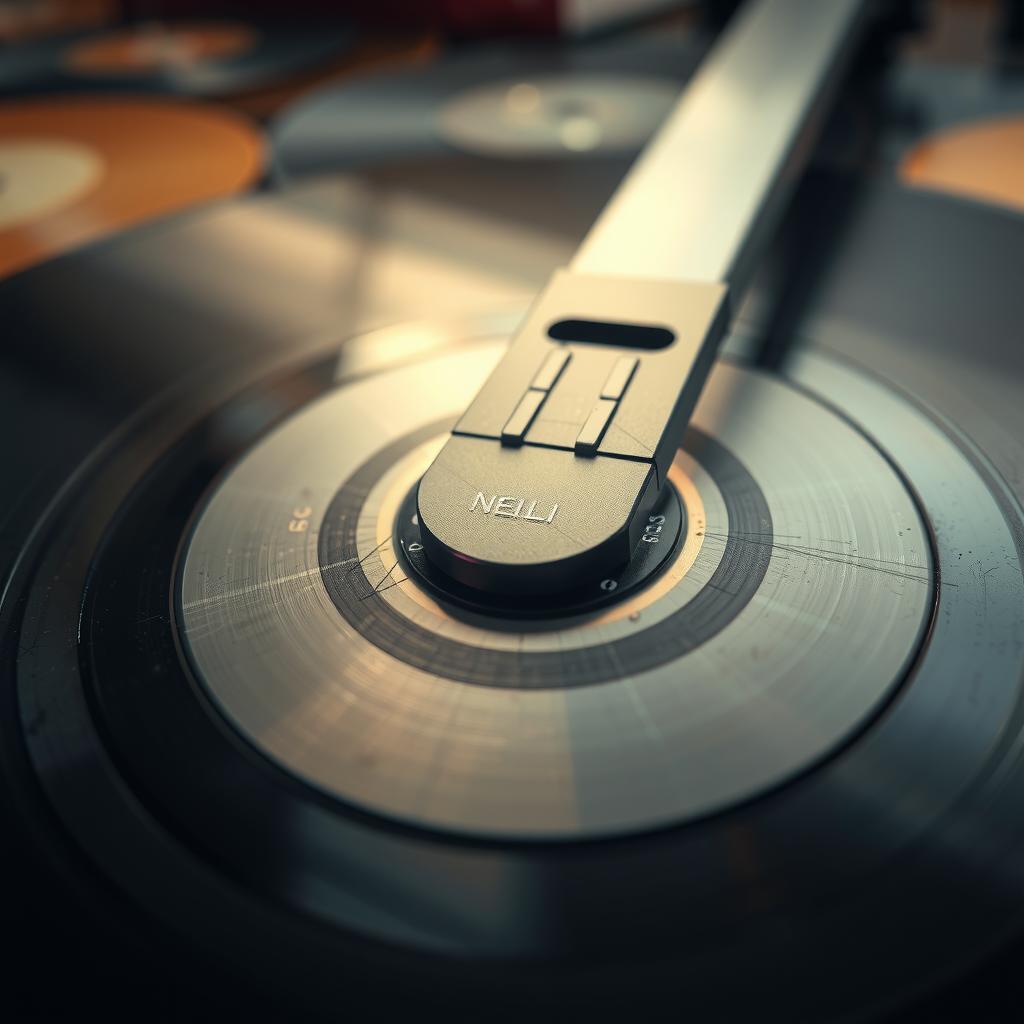

In the realm of vinyl records, there exists a subtle yet critical element that often goes unnoticed—the wear on phonograph needles. Have you ever wondered how much the quality of your beloved record collection might be compromised by a worn-out needle? For audiophiles and casual listeners alike, maintaining optimal sound reproduction is essential for enjoying those rich, warm tones that only vinyl can provide. However, without proper attention to needle maintenance, the performance of both the cartridge and overall audio experience may suffer significantly.

This blog post aims to uncover the importance of phonograph needle wear indicators—a game-changer for anyone invested in preserving their music’s integrity. These handy tools not only help gauge when it’s time to replace a needle but also ensure that your listening sessions remain pristine and enjoyable. Imagine being able to extend the lifespan of your cartridges while simultaneously enhancing sound clarity; this is where these wear indicators come into play.

As users dive deeper into their passion for collecting vinyl, they quickly realize that even minor imperfections in playback can detract from their enjoyment. A worn phonograph needle can lead to distortion, skipping tracks, or worse yet—a damaged record surface. The need for awareness surrounding these issues has never been greater, as enthusiasts strive not just for quantity but quality in their collections. By utilizing effective wear indicators, one can regularly monitor the condition of their equipment and make timely replacements before any irreversible damage occurs.

Moreover, understanding how wear affects audio performance underscores why it’s crucial to integrate such monitoring systems into regular vinyl care routines. In this discussion about phonograph needle wear indicators, readers will find insights into selecting appropriate products tailored specifically toward enhancing longevity and fidelity during each spin on turntables across various setups.

Thus begins an exploration designed not just for seasoned collectors but also newcomers eager to learn about best practices in maintaining their precious vinyl records through innovative solutions like phonograph needle wear indicators. Join us as we delve deeper into how these tools work and why they are indispensable allies in achieving unparalleled listening experiences with every album played.

Key Points:

-

Importance of Monitoring Needle Condition: Understanding the impact of phonograph needle wear indicators on audio fidelity and sound reproduction is essential for any vinyl enthusiast. These tools provide crucial insights into the condition of the phonograph needle, allowing users to maintain optimal audio quality.

-

Visual Cues for Replacement: The integration of wear indicators into routine needle maintenance practices empowers audiophiles to identify when their needles require replacement. By recognizing these visual cues early, listeners can protect their vinyl records from potential damage caused by worn-out needles.

-

Enhancing Cartridge Performance: Accessing reliable phonograph needle wear indicators not only serves as a preventive measure but also enhances overall cartridge performance. Regularly checking these indicators helps ensure that music playback remains clear and rich, ultimately elevating the listening experience for all who cherish their collections.

The Significance of Phonograph Needle Wear

Unveiling the Effects on Audio Fidelity

Phonograph needle wear is an often-overlooked aspect of vinyl record playback that significantly impacts audio fidelity and the overall listening experience. As a phonograph needle, also known as a stylus, makes contact with a spinning record, it encounters friction that gradually leads to wear over time. This degradation can manifest in various forms, including bluntness or damage to the tip of the needle, which directly affects its ability to accurately trace the grooves on a record. Consequently, this results in distorted sound reproduction and diminished highs and lows in audio quality. Many audiophiles may not realize how crucial regular inspection for phonograph needle wear indicators is to maintaining optimal sound performance. Ignoring these signs can lead listeners down a path where they settle for subpar experiences instead of enjoying rich layers of music captured within their beloved vinyl records.

The Mechanics Behind Needle Maintenance

Understanding How Maintenance Affects Listening Experience

For those invested in preserving their auditory experience, understanding proper maintenance techniques is essential when it comes to phonograph needles. Regular cleaning plays an integral role; dust and debris accumulation can exacerbate wear while compromising cartridge performance during playback. Utilizing appropriate cleaning tools tailored specifically for styluses helps minimize this risk by ensuring that any foreign particles are removed without causing additional harm to delicate components like diamond tips found on most modern needles. Furthermore, knowing when to replace your stylus based on visible wear indicators—such as increased surface roughness or changes in shape—can drastically improve sound reproduction quality over time. Neglecting these aspects could lead audiophiles toward frustration as they find themselves experiencing muddled sounds or unwanted pops during listening sessions—a stark contrast from what well-maintained equipment should provide.

Indicators of Needle Degradation

Recognizing Signs Before It’s Too Late

Identifying early warning signs is pivotal for anyone keen on preserving audio integrity through careful management of their phonographic gear. Commonly recognized phonograph needle wear indicators include irregularities such as uneven groove tracking or sudden spikes in distortion levels during playback; both suggest significant damage has occurred either at the tip itself or elsewhere along its length due to excessive use without adequate care measures being taken beforehand. Additionally, discerning listeners might notice shifts within tonal balance across frequencies—a clear signal indicating that immediate attention should be given towards evaluating one’s current setup before further deterioration jeopardizes cherished recordings permanently! By regularly assessing these factors against established benchmarks regarding acceptable performance metrics derived from high-quality vinyl records ensures enthusiasts stay ahead amidst inevitable aging challenges inherent with traditional analog systems.

Consequences of Neglected Needles

Exploring Long-Term Effects on Sound Quality

Failure to address issues surrounding needle maintenance ultimately leads not only towards compromised enjoyment but potentially irreversible damage inflicted onto precious collections amassed over years spent curating favorites within one’s library! Beyond simply losing clarity and detail present throughout familiar tracks lies another concern: repeated playthroughs using worn-out phono cartridges risks creating permanent scratches upon surfaces intended solely for exquisite sonic exploration—the very reason collectors invest so heavily into acquiring pristine pressings originally crafted by skilled artisans committed toward producing beautiful art forms we adore today! Given this reality underscores why acknowledging necessary upkeep methods alongside vigilance concerning potential deterioration remains paramount among vinyl aficionados seeking unparalleled delight rooted deep inside every spin enjoyed together around turntables worldwide—you owe yourself nothing less than perfection!

Conclusion: Embracing Awareness for Enhanced Listening

Prioritizing Careful Attention Towards Equipment

In conclusion—and perhaps most importantly—it becomes evident how intertwined our love affair with music played via analog formats connects intimately back again towards responsible handling practices adopted whenever engaging directly alongside instruments fueling passion-driven pursuits experienced firsthand through dynamic environments filled vibrancy captivating audiences everywhere alike! By prioritizing knowledge about proper monitoring techniques focused squarely aimed at recognizing common pitfalls commonly associated with neglecting basic principles governing effective usage guidelines laid out previously depicted here ensure vibrant insights flourish freely unfettered allowing timeless treasures once thought lost return alive anew just beyond fingertips poised ready take flight soaring upwards reaching heights unknown paving way onward forging paths leading joyfully forward embracing future adventures awaiting all who dare dream big amidst wondrous realms beckoning ever closer still beckoning call forth inviting journeys yet undertaken continue unfolding beautifully revealing secrets waiting patiently shared each moment lived fully embraced cherished dearly forevermore lingering long after fading echoes disappear gently whispering memories held dear deep within hearts touched profoundly transformed eternally changed shaped lives woven intricately together timeless tapestry life celebrates endlessly…

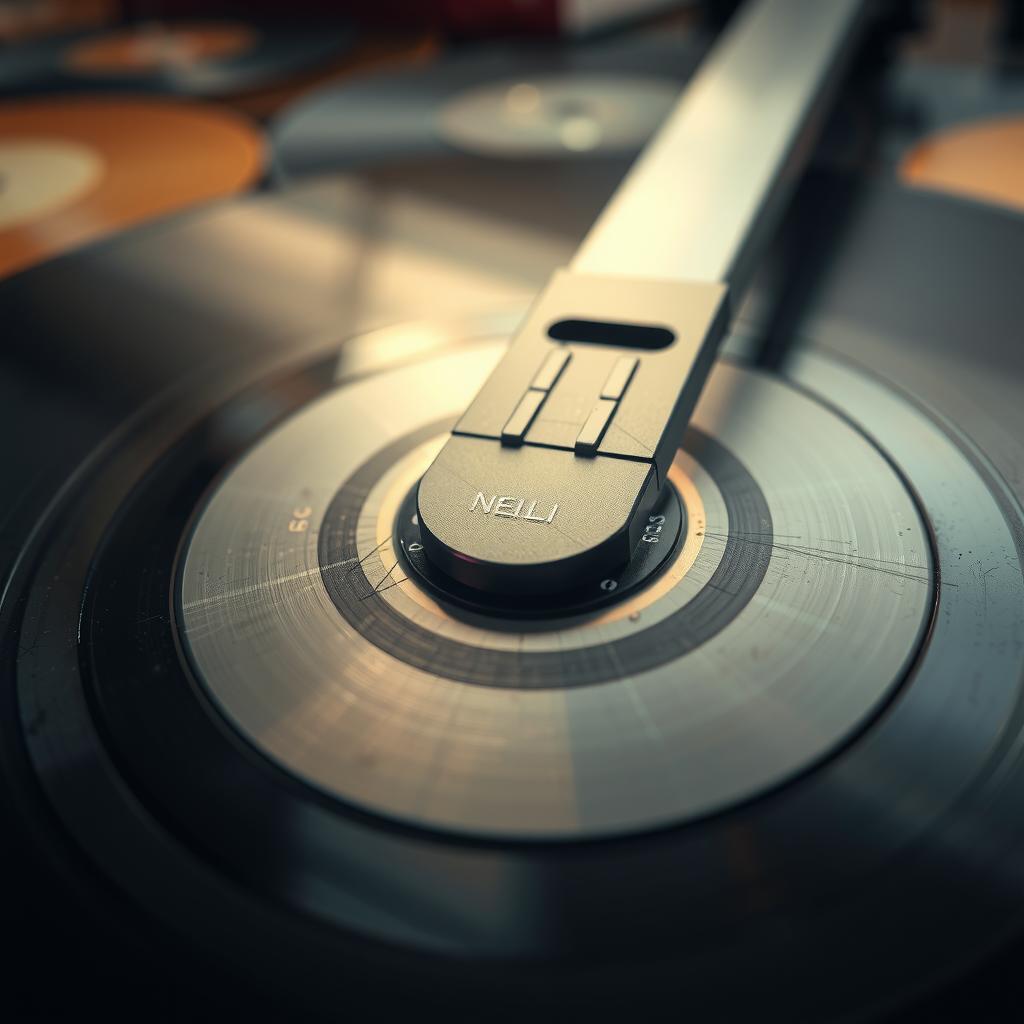

The Crucial Role of Wear Indicators in Turntable Maintenance

Ensuring Optimal Sound Quality and Longevity

For audiophiles, the quest for pristine sound reproduction is paramount, and this pursuit heavily relies on the condition of their equipment. One essential tool that plays a significant role in maintaining turntable performance is phonograph needle wear indicators. These indicators serve as a visual cue to assess the wear on a cartridge’s stylus, ensuring that users can replace or maintain their needles before they cause irreversible damage to precious vinyl records. A worn-out needle not only degrades audio quality but also accelerates record wear, leading to diminished sound fidelity over time. By incorporating wear indicators, enthusiasts can proactively monitor their setup’s health, allowing them to preserve both their music collection and investment in high-quality audio gear.

Understanding Needle Maintenance for Audiophiles

Enhancing Your Listening Experience

Proper maintenance of the phonograph needle is crucial for achieving optimal audio performance, making needle maintenance an integral part of any audiophile’s routine. Regularly checking these phonograph needle wear indicators allows listeners to identify when it’s time for replacement or servicing before any noticeable degradation in sound occurs. This diligence ensures that records are played back with clarity and accuracy; otherwise, distortion becomes evident as grooves are damaged by an ineffective stylus. Moreover, investing time into understanding how different cartridges perform with various genres can further enhance one’s listening experience—after all, the relationship between a well-maintained needle and superior sound reproduction cannot be overstated.

The Impact of Cartridges on Vinyl Playback

Maximizing Turntable Efficiency

The choice of cartridge significantly impacts overall playback quality; thus, knowing when your phonograph needle needs attention is vital for maximizing turntable efficiency. Utilizing wear indicators helps audiophiles closely monitor how much life remains within their stylus while simultaneously safeguarding against potential pitfalls associated with neglecting this aspect of equipment upkeep. As seasoned listeners will attest, even minor changes in cartridge performance due to improper care can lead to substantial declines in audio enjoyment from treasured collections—especially when it comes down to intricate nuances found within complex compositions or live recordings that demand precise tracking capabilities from the stylus system itself. By adhering strictly to routines involving monitoring through these simple yet effective tools like phonograph needle wear indicators, enthusiasts ensure prolonged lifespan not just for their styli but also elevate every listening session into something truly exceptional.

The Importance of Needle Maintenance in Vinyl Playback

Preserving Audio Quality with Proper Care

Maintaining the phonograph needle is crucial for anyone who appreciates vinyl records and wants to preserve their audio quality. A well-cared-for needle can significantly enhance sound reproduction, allowing listeners to experience the full depth and richness of their favorite tracks. Regular inspection and cleaning should be part of a dedicated maintenance routine; dirt, dust, or any residue on the needle can lead to distortion or damage both to the phonograph needle itself and the delicate grooves of vinyl records. Implementing good practices like using a soft brush specifically designed for this purpose helps remove particles that can accumulate over time. Additionally, employing phonograph needle wear indicators will assist users in monitoring their needles’ condition effectively—these indicators provide visual cues that alert users when it’s time for replacement or servicing.

Techniques for Effective Needle Care

Effective care techniques go beyond simple cleaning; they also encompass understanding how environmental factors impact performance. Humidity levels, temperature fluctuations, and even improper storage conditions can adversely affect both cartridge performance and overall playback quality. It’s advisable to store records vertically in a clean environment away from direct sunlight while ensuring that your turntable setup is free from vibrations caused by nearby speakers or heavy foot traffic areas which could further compromise sound reproduction. Users should familiarize themselves with specific needle maintenance products available on the market including specialized cleaners designed not only for needles but also to protect vinyl surfaces during playback sessions. By regularly checking alignment through tools such as protractors or laser alignment devices coupled with close attention paid towards those essential wear indicators, audiophiles can optimize their listening experiences.

Recognizing When Repair Is Necessary

Understanding when repair is necessary hinges upon being informed about key signs that indicate declining performance levels of a phonograph needle. Common symptoms include increased surface noise during playbacks such as crackling sounds which may suggest wear has occurred over time due to continued usage without adequate upkeep measures taken beforehand – hence why it’s vital always keep an eye out for those wear indicators! Furthermore, if one notices skipping portions within tracks where there were none previously might imply misalignment issues requiring immediate adjustment before further damaging either your precious records or degrading overall audio fidelity through compromised stylus interaction with groove structures present on vinyl formats alike.

Enhancing Sound Reproduction Through Consistent Checks

A consistent check-up routine serves not just as preventive maintenance but elevates long-term satisfaction derived from listening experiences too! Audiophiles are encouraged not merely wait until problems arise before acting; instead making it habitually engage in regular assessments that promote longevity among all equipment used throughout usual record-playing sessions – especially considering how critical these components are towards achieving optimum sound reproduction results each time music plays through speakers surrounding them! Utilizing established schedules based around usage frequency paired up tightly alongside recommendations provided by manufacturers ultimately leads back toward discovering superior auditory delights found across genres ranging widely across different eras captured beautifully onto timeless discs crafted carefully into collections cherished dearly by enthusiasts everywhere today!

Frequently Asked Questions:

Q: How do I know when my phonograph needle needs to be replaced?

A: Monitoring the condition of your needle is essential for maintaining optimal audio quality. Phonograph needle wear indicators provide visual cues that indicate the state of your stylus. When these indicators show significant wear, it’s time to replace your needle to prevent potential damage to both the cartridge and your cherished vinyl records.

Q: Can a worn phonograph needle affect sound reproduction?

A: Yes, a worn-out phonograph needle can drastically alter sound reproduction. As the tip of the stylus wears down, it may not make proper contact with record grooves, leading to distortion and reduced fidelity. Utilizing wear indicators allows audiophiles to maintain their equipment’s performance and preserve clarity in music playback.

Q: What are some signs that I need better needle maintenance?

A: Besides relying on phonograph needle wear indicators, users should watch for signs like skipping or crackling sounds during playback, which could indicate that the stylus is damaged or excessively worn. Regularly checking these visual cues ensures proper needle maintenance and helps protect both high-quality cartridges and valuable vinyl collections from degradation over time.